Closed-Loop System

Superior Control, Maximum Purity

PHB’s industry-leading closed-loop manufacturing system provides an unrivaled level of control over the sourcing, production, and distribution of animal extracts and purified proteins. Our process minimizes the chances of environmental contamination, which results in exceptionally pure and reliable products.

Collection

PHB only collects USDA/MPI-certified raw materials from exclusive abattoirs. The material undergoes a thorough inspection before being collected through our proprietary collection process.

Transport

Once collected, raw material is immediately transferred directly to our manufacturing facilities, contained entirely in transport equipment designed to prevent contamination.

Manufacturing

The raw material is transferred into the facility via direct lines, eliminating interaction with the external environment. The material is manufactured through closed tanks, lines, filters, and separation equipment. There are no exposed filter presses or open tanks, nor is any non-food grade or noxious solvent material introduced into the process.

Advantages of the Closed-Loop System

Minimum Exposure to Environmental Contaminants

Raw Materials Sourced only from USDA/MPI-Certified Sources

Greater Accuracy and Reliability in Diagnostic uses

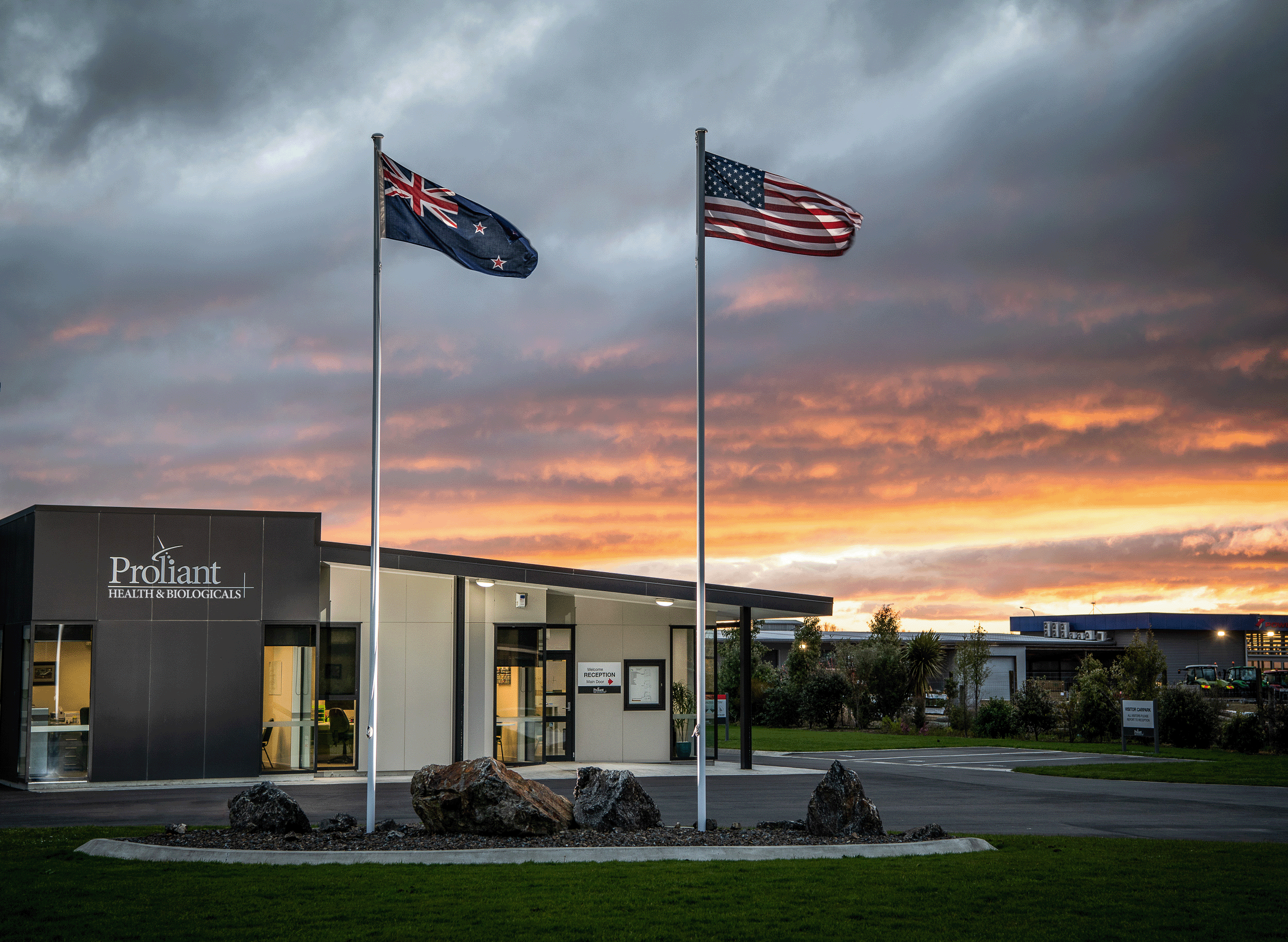

World-Class Manufacturing Across the Globe

PHB houses its closed loop manufacturing process in two identical facilities around the world.

The Agriscience Center of America

New Zealand’s Agricultural Hub

Closed-Loop Resources

Learn more about how the closed-loop system produces better products

We’re ready to answer your questions about our closed-loop system.